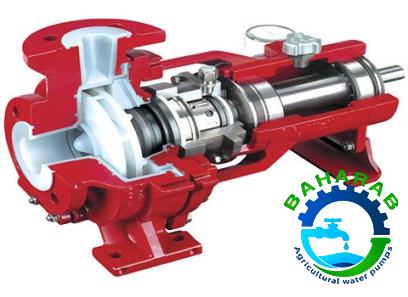

Centrifugal pumps are essential components in various industries, playing a critical role in moving fluids efficiently and effectively. These pumps utilize the principles of centrifugal force to generate kinetic energy, which is then converted into pressure to transport liquids from one place to another. With their simple design, high flow rates, and ease of maintenance, centrifugal pumps have become a popular choice for a wide range of applications. One of the key advantages of centrifugal pumps is their ability to handle a diverse array of fluids, from water and chemicals to oil and slurry. This versatility makes them suitable for use in industries such as agriculture, manufacturing, mining, and wastewater treatment. In agricultural settings, centrifugal pumps are commonly used for irrigation, crop spraying, and livestock watering. Their ability to handle corrosive and abrasive fluids also makes them ideal for industrial processes that involve the transfer of chemicals and slurries.

.

Centrifugal pumps can be classified into various types based on their specific design characteristics and operating principles. Single-stage centrifugal pumps feature a single impeller and are suitable for applications with moderate flow rates and pressure requirements. These pumps are commonly used in HVAC systems, water supply, and general fluid transfer applications. In contrast, multistage centrifugal pumps incorporate multiple impellers arranged in series to achieve higher pressures. These pumps are ideal for boosting water pressure, such as in municipal water supply systems, high-rise buildings, and industrial processes that require high-pressure fluid delivery. In addition to single-stage and multistage designs, centrifugal pumps can also be categorized based on the orientation of the pump shaft. Horizontal centrifugal pumps have the shaft positioned horizontally, parallel to the ground, and are commonly used in industrial and commercial applications where space is available. Vertical centrifugal pumps, on the other hand, have the shaft positioned vertically, with the pump impeller submerged in the fluid being pumped. Vertical pumps are often used in applications where space is limited, such as in sump pumps, deep well pumping, and certain industrial processes.

Centrifugal pumps can be classified into various types based on their specific design characteristics and operating principles. Single-stage centrifugal pumps feature a single impeller and are suitable for applications with moderate flow rates and pressure requirements. These pumps are commonly used in HVAC systems, water supply, and general fluid transfer applications. In contrast, multistage centrifugal pumps incorporate multiple impellers arranged in series to achieve higher pressures. These pumps are ideal for boosting water pressure, such as in municipal water supply systems, high-rise buildings, and industrial processes that require high-pressure fluid delivery. In addition to single-stage and multistage designs, centrifugal pumps can also be categorized based on the orientation of the pump shaft. Horizontal centrifugal pumps have the shaft positioned horizontally, parallel to the ground, and are commonly used in industrial and commercial applications where space is available. Vertical centrifugal pumps, on the other hand, have the shaft positioned vertically, with the pump impeller submerged in the fluid being pumped. Vertical pumps are often used in applications where space is limited, such as in sump pumps, deep well pumping, and certain industrial processes.

..

In recent years, advancements in centrifugal pump technology have led to the development of innovative features and improvements that enhance pump performance and efficiency. Variable frequency drives (VFDs) are commonly used with centrifugal pumps to control motor speed and optimize energy consumption based on system demand. By adjusting the pump speed to match flow requirements, VFDs help reduce energy costs and extend the pump’s service life. Additionally, pump manufacturers have introduced smart pump technology that integrates sensors and monitoring systems to provide real-time performance data, predictive maintenance alerts, and remote monitoring capabilities. The selection and installation of centrifugal pumps require careful consideration of various factors to ensure optimal performance and longevity. Factors such as fluid properties, flow rate, pressure requirements, system layout, and environmental conditions must be evaluated to choose the right pump design and specifications. Proper pump sizing, installation, and maintenance are essential to maximize pump efficiency, minimize energy consumption, and prevent premature wear and component failure.

In recent years, advancements in centrifugal pump technology have led to the development of innovative features and improvements that enhance pump performance and efficiency. Variable frequency drives (VFDs) are commonly used with centrifugal pumps to control motor speed and optimize energy consumption based on system demand. By adjusting the pump speed to match flow requirements, VFDs help reduce energy costs and extend the pump’s service life. Additionally, pump manufacturers have introduced smart pump technology that integrates sensors and monitoring systems to provide real-time performance data, predictive maintenance alerts, and remote monitoring capabilities. The selection and installation of centrifugal pumps require careful consideration of various factors to ensure optimal performance and longevity. Factors such as fluid properties, flow rate, pressure requirements, system layout, and environmental conditions must be evaluated to choose the right pump design and specifications. Proper pump sizing, installation, and maintenance are essential to maximize pump efficiency, minimize energy consumption, and prevent premature wear and component failure.

…

In conclusion, centrifugal pumps are versatile, efficient, and reliable fluid handling solutions that play a crucial role in a wide range of industries and applications. Their ability to generate high flow rates, handle diverse fluids, and operate over a wide range of pressures make them a cost-effective choice for fluid transfer needs. By understanding the key design principles, types, and features of centrifugal pumps, operators can make informed decisions when selecting, installing, and maintaining these essential components in their systems. With ongoing advancements in technology and engineering, centrifugal pumps continue to evolve to meet the growing demands of modern industries and ensure efficient fluid handling solutions for years to come.

In conclusion, centrifugal pumps are versatile, efficient, and reliable fluid handling solutions that play a crucial role in a wide range of industries and applications. Their ability to generate high flow rates, handle diverse fluids, and operate over a wide range of pressures make them a cost-effective choice for fluid transfer needs. By understanding the key design principles, types, and features of centrifugal pumps, operators can make informed decisions when selecting, installing, and maintaining these essential components in their systems. With ongoing advancements in technology and engineering, centrifugal pumps continue to evolve to meet the growing demands of modern industries and ensure efficient fluid handling solutions for years to come.

Your comment submitted.